Key Considerations in Fire Pump Design and Installation

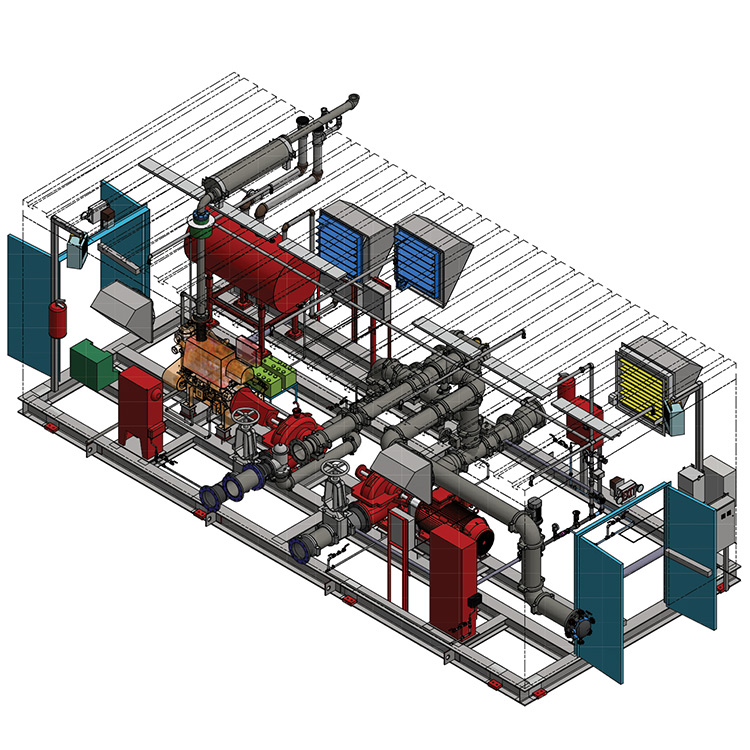

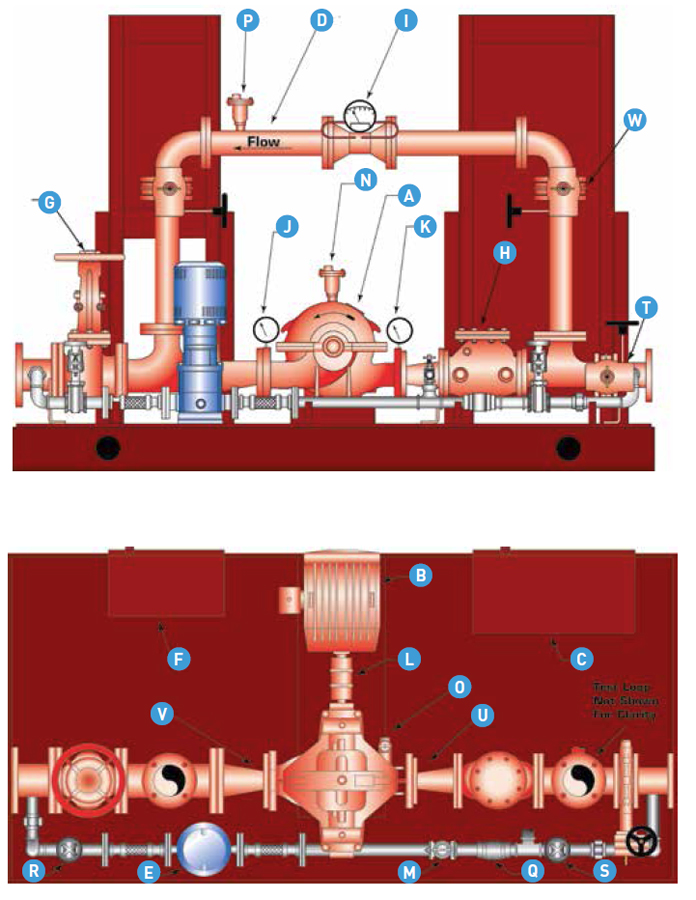

In addition to addressing the more obvious components that comprise a fire pump installation - such as the fire pump, driver, controller, and pump room-careful attention also needs to be given to the piping leading to, from, and around the pump and the equipment associated with that piping.

fire pump installation details YouTube

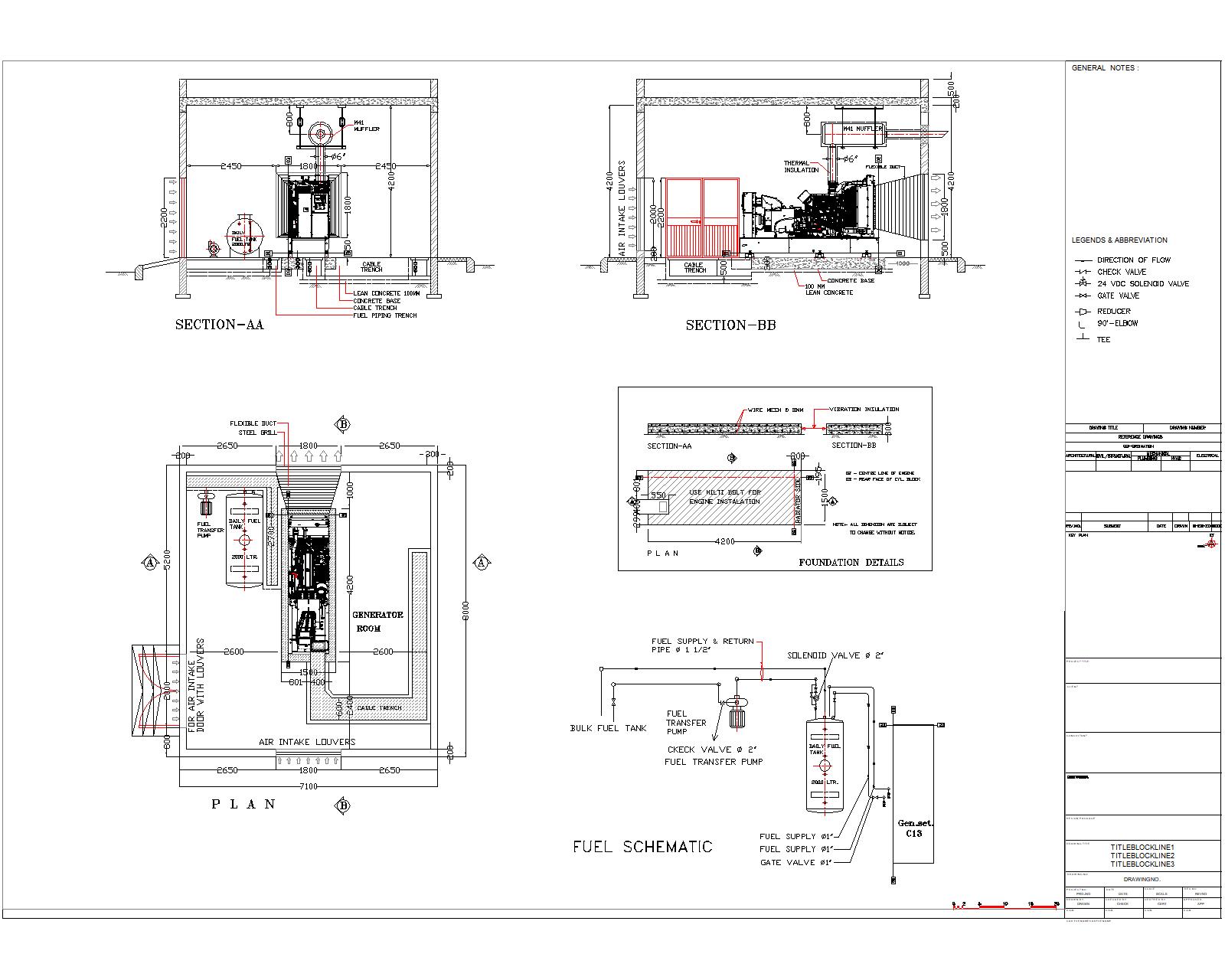

These supervisory conditions are verified by the fire protection and electrical experts during commissioning of a fire pump at the installation site. As we know, many requirements of NFPA 20 have been already incorporated in Rule 32-206 of the CEC. These requirements include a need for a separate automatic transfer switch for each fire pump and.

Packaged fire pump installation instructions 911Pump Better

Aug 11, 2023 Share: Installing a fire pump properly is essential to ensure its reliability and effectiveness during emergency situations. Below is a general guide for fire pump installation, but always refer to the manufacturer's specific installation instructions and any relevant local codes and regulations: Pre-Installation Preparation:

Fire Pump Schematic Diagram

The fire pump is a crucial element to a building's fire sprinkler system. Fire pumps are typically made with no-corrosive internal parts to avoid clogging due to corrosion. To avoid cavitation and to have a stable system pressure, the fire pumps are designed specifically for adequate water supply purposes, with strict requirements.

Aurora Packaged Fire Pump Systems Fox Valley Fire & Safety

1.0 Installation 1.1 Location and storage 1.2 Foundation for hsc pump 1.3 Pump mounting and piping 1.4 Alignment 1.5 Minimum fittings 2.0 Operation-electric driven 2.1 Prestart-up 2.2 Pressure switch setting 2.3 Circulation relief valve 2.4 Start-up procedure Electric driven Diesel engine driven 2.5 Automatic operation 3.0 Maintenance

Nfpa 20 Fire Pump Installation

A fire pump is any type of purpose-driven pump used within a fire protection system. It can be driven by diesel engines, electric motors or even steam and is used to provide increases in water pressure to meet the design requirements of a fire protection system. Fire pumps do not create a water supply.

Fire Pump Installation Fire Protection Florida Sprinklermatic

1- Gate valve 2- check valve 3- Suction header 4- Discharge header 5- Diesel pump 6- Jockey pump 7- Electric pumps 8- Pressure relief valve 9- Alarm check valve 10- Water flow meter 11- Diesel pump electric control panel and pressure sensing line 12- Jockey pump electric control panel and pressure sensing line

2. Typical installation of firefighting units with vertical turbine pumps

Fire pump intakes are connected to underground public water supply piping, or a tank or reservoir located onsite, to provide water flow at a higher pressure to the sprinkler system risers and hose standpipes. Fire pumps are activated when the water pressure in the system drops below a certain threshold.

NFPA20 compliant Fire Pump House

If you follow NFPA 20, "Standard for the Installation of Stationary Pumps for Fire Protection," then you'll want to install emergency lighting in the pump room per Sec. 5.12.4 and remote monitoring per Sec. 10.4.7.1. Even if it's not required, a monitoring system is a sound idea.

Standard Fire Pump Generator (mechanical) CAD Files, DWG files, Plans

Electrical systems for fire pumps are governed specifically by NEC Article 695. This article includes all of requirements for normal and alternate sources of power for fire pumps.

PJH Fire Sprinkler Design, L.L.C. Sample Drawings

Fire pumps are an essential part of most fire protection systems, as they allow for taller buildings, smaller piping and higher pressure and flow rates in systems. Incorrectly sized or selected pumps can result in not enough pressure or flow being created, which can cause several problems: Systems function incorrectly.

Complying with fire pump standards Pump Industry Magazine

The items below serve as a basic checklist of additional coordination items not previously discussed. Points on the fire protection system monitored by the fire alarm system such as fire pump status, control valve positions, waterflow and tamper switches. The approved audible alarm device required per IBC 903.4.2.

Fire pump settings NFPA 20 Fire Protection Specialists

For this blog, we feature an installation in Phoenixville, PA, installed by H & H Systems, Inc. The installation is of a Peerless horizontal split-case fire pump, along with controller, jockey pump, and accessories. As with many new installations, there is not a lot of space in this particular mechanical room.

Fire Pump Installation in NH & CT Fire Pump & Sprinkler Installation

1. A circuit breaker designed for installation in a normal power supply circuit, upstream of thecircuit breaker in a fire pump controller (see diagram 2) should be selected with aninstantaneous trip setting at 21 times of the full-load current and with thermal/locked rotorovercurrent protection setting at 350% of the motor full-load current. 2.

Aurora Packaged Fire Pump Systems Fox Valley Fire & Safety

Centrifugal Fire Pumps: Centrifugal fire pumps are widely used due to their efficiency and reliability in supplying water to fire suppression systems. Our experts are well-versed in the installation of centrifugal fire pumps, ensuring proper alignment, piping connection, and integration with the existing fire protection infrastructure.

Fire Fighting Pump Connection Details & Its Working. YouTube

The primary design references for fire pump installations are NFPA 20 Installation of Centrifugal Fire Pumps, Unified Facilities Criteria (UFC) 3-600-01 Design: Fire Protection Engineering for Facilities. The Designer will coordinate this specification section with any applicable contract sprinkler system.